|

|

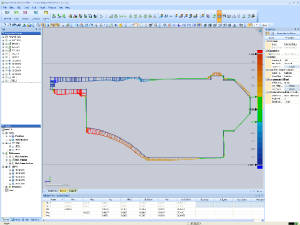

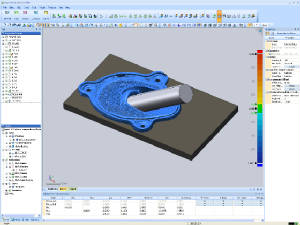

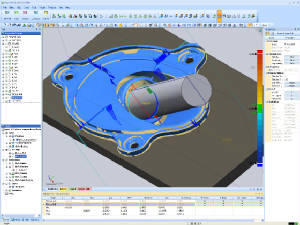

One of the great advantages of white light digital scanning is

that you capture the whole part. Unlike a CMM inspection, digital scanning captures literally thousands of points.

When this is applied to part inspection, it gives the most detailed analysis possible. With Rapidform XOV inspection

software, we can give you an accurate report which can include cross sections, GD&T dimensioning, space point checks,

part edge analysis, etc..... Free Rapidform Explorer viewer software is available by using the download path on our

"Links" page. Using this viewer software allows you 3D, rotational and interactive viewing of an XOV inspection

file. This part had an issue with excessive shrinkage

in a few areas. We scanned the part and overlayed it to the CAD data. Using Rapidform XOV, sections were cut along

with checking some critical dimensions. This data was then used to make necessary changes to the part so it would work

better with its mating piece. (Click on images to enlarge)

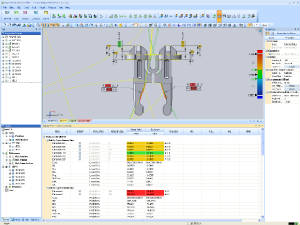

A concentricity check was needed between a drive

shaft bushing and its test fixture. We scanned the parts and the fixture separately. The scans were then aligned

using the mounting holes and planar mounting surface. We could then check the concentricity of the drive shaft to the

bushing in Rapidform XOV. (Click on images to enlarge)

|

Archiving | Reverse Engineering | Troubleshoot Tooling | Work Holding Solutions | 1st Article Inspection

Thank you for visiting our website!