|

|

October, 2016 - July, 2017

In January of 2017, we purchased a new OR Laser EVO Mobile

CNC micro welder. This is a nice addition to our two current manual micro welding stations which are used for mold

repair. The new CNC micro welder expands our capabilities to better serve those in need of this specialized application.

To see the CNC micro welder working, click HERE for a short YouTube presentation.  July, 2014 - October, 2016

Over the past 26 months, we have continued to add new machinery to

keep up with increasing demands at the B&J Specialty facility. We have acquired two more YCM

vertical milling centers. Again, two NDV 102As with a spindle speed of 20,000rpm. In addition,

we have purchased a new Sodick AG100L CNC sinker EDM. It has a C-axis work tank size of 82.68" x 49.21" x

25.59". Travel specs are X47.24", Y25.59", Z19.69". Work piece max weight is 11,023 lbs.

It is pictured below.  We have also recently purchased a 3D Systems ProX DMP 300 3D direct metal printer.

We will be concentrating on printing with maraging steel. This is an equivalent to H-13 tool steel. It can be

heat treated, machined, polished and coated. In reality, it is more dense than billet stock steel. Printing

size capabilities are approximately 10" X-axis x 10" Y-axis x 13" Z-axis. We would be happy

to fulfill any metal 3D printing needs you have. Please contact Jarod Rauch for quoting and general information

about metal 3D printing. To contact Mr. Rauch, just LMB click on the "Contact Us" link on the menu

choices at the left side of this page. LMB click the picture below to take you to our Metal 3D Printing website. You

can see our 3D Printer working, along with some samples, on our YouTube channel by clicking HERE. September, 2013 - July, 2014

Over the past 9 months, we have continued to add new machinery to

keep up with increasing demands at the B&J Specialty facility. We have acquired another YCM vertical

milling center. This time, the NDV 102A with a spindle speed of 20,000rpm. Also, the recent purchase

of a DCV 2012B vertical milling center with a spindle capability of 15,000rpm. If you click on the

photos below, it will automatically link you to each respective CNC mill's specifications.

We have also recently purchased a Makerbot Replicator 2 3D printer. It 3D prints plastic parts with PLA, which is a corn based bio-degradable plastic. Printing size capabilities are 12" X-axis x 6" Y-axis x 6" Z-axis. We would be happy to fulfill any 3D printing needs you have. Please contact David Chrisman for quoting and general information about 3D printing. To contact Mr. Chrisman, just LMB click on the "Contact Us" link on the menu choices at the left side of this page.

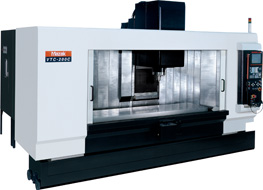

March, 2012- September, 2013 Over the past 18 months, we have made many upgrades to our vertical

CNC machining capabilities. Not only have we phased out 3 CNC mills, we added an additional CNC mill to help keep

up with customer demands. We have acquired 2 Mazak VTC-300C vertical milling centers with 12,000rpm spindles and 2 YCM

NTV-158B vertical milling centers with 15,000rpm spindles. If you click on the photos below, it will automatically

link you to each respective CNC mill's specifications.

February, 2012

B&J Specialty has upgraded from our GOM white light scanning system to a brand new Steinbichler L3D Comet blue light scanner and the Comet/Nikon photogrammetry system. Steinbichler is a world wide leader in digital measuring systems and we are excited to offer the latest in digital

scanning technology to our customers. For quoting or questions about our scanning capabilities, please contact David

Chrisman at 1-260-761-5011 x114 or by e-mail at dchrisman@bjspecialtyinc.com. B&J Specialty has upgraded from our GOM white light scanning system to a brand new Steinbichler L3D Comet blue light scanner and the Comet/Nikon photogrammetry system. Steinbichler is a world wide leader in digital measuring systems and we are excited to offer the latest in digital

scanning technology to our customers. For quoting or questions about our scanning capabilities, please contact David

Chrisman at 1-260-761-5011 x114 or by e-mail at dchrisman@bjspecialtyinc.com.  ©copyright 2009-2017 B&J Specialty, Inc. All rights reserved.

|

Thank you for visiting our website!