|

|

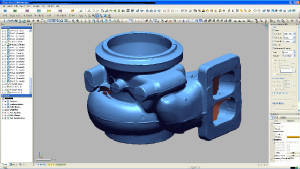

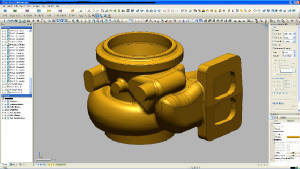

Often times, lathe or CNC milling work needs performed on raw

castings or custom objects. It is quite common for these castings to be formed from very old patterns which have no

engineering data. Also, custom or altered objects commonly have no updated engineering data. In these cases, white

light scanning is a perfect solution to provide a model of the casting or altered object. With the newly generated model,

work holding fixtures can be created for the work piece allowing for ease of machining. A few examples are below. No CAD data existed for a variety of turbine castings.

Our customer needed to make work holding jaws so lathe and NC machining could be performed on the castings. We scanned

each different style of casting, created a model with Rapidform XOR, and our customer developed their work holding jaws from

the model.

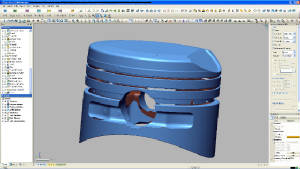

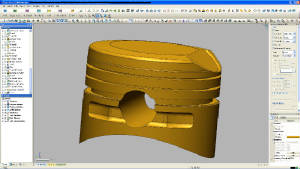

A well known racing team in Indianapolis makes modifications

to stock racing components on a regular basis. Obviously, no CAD data accompanies the purchase of such

items. They come to B&J Specialty, Inc. for the scanning and modeling of pieces such as the pistion shown at

left. We provide them with 3D CAD data so they can make modifications as needed to get the most output from their racing

components.

|

Thank you for visiting our website!